1394 mm 10 mm to 10 mm. If you need help with aligning your car give us a call at Callahan Automotive today.

Shaft Alignment Know How 5 Step Shaft Alignment Procedure Youtube

Investigating and analysing incidents will also make a big contribution to understanding.

. Spirit Level Method This tool is appropriate for controlling verticality of small scale works for example checking formworks and door frames. Positions 9 12 3 and 6. Segregate and dispose defective measuring instruments to avoid wrong usage.

Practise use of further measurement techniques on a range of products. Preparation for and completion of Assignment 2. Angular Alignment This method can be used by inserting a feeler gauge and here are the steps listed below.

The main m easurement testing and control instruments are limit gauges measurement templates and semiautomatic measurement instruments. It is important to note that the laser beam will not be perfectly centered or parallel to the axis of rotation and may appear to be off the center of the tailstock centerline this is normal. 31 mm to 60 mm.

Insert the feeler gauge between the coupling faces of the shafts After the feeler gauge is put both couplings are rotated half way simultaneously The readings on the feeler gauge are checked at four points on the shaft coupling. Using Measurement Equipment and Techniques P4 P5 and M1. Performing alignment testing regularly on critical machines can help in early identification of misalignment and alignment-related problems thus minimizing the risk of unplanned downtime increased parts costs and more frequent component replacement.

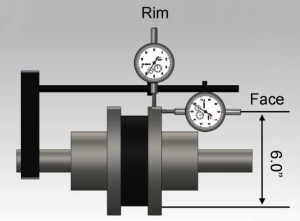

Choose an appropriate method to collect data on an. To check camber make sure the vehicle is parked on level ground. In this method two dial indicator rim and face dial are used to determine the relative position of movable shaft with respect to stationary shaft.

Equipment and materials used must be appropriate to the work area and handled correctly to ensure safety of personnel. Then place a straight edge across the wheel use the inner lip if the outer is nicked or uneven and use an angle finder to reveal camber. 1435 mm 10 mm up to 40 mm.

Describe the methods and techniques used to dismantleassemble mechanical equipment such as release of pressuresforce proof marking extraction pressing alignment Proof marking using centre punch or scribe tool can be used to make references whilst dismantling in order to more easily reassemble components. Constant vigilance by both workers and supervisors is necessary to eliminate hazardous conditions that could cause a. Checking involves setting up an effective monitoring system backed up with sensible performance measures.

Rim and Face Alignment Method Rim and Face alignment method are oldest method used for shaft alignment of misaligned equipmentshaft. Use only appropriate measuring equipment for the specific parts to be measured. Consider a recuperative cross flow heat exchanger both fluids unmixed used in a gas turbine system that carries the exhaust gases at a flow rate of 75 kgs and a temperature of 500circ C The air initially at 30circ C and flowing at a rate of.

The PI docu ments any specific procedure in. Contact the maker of measuring equipment if major problem was occurred on the said instrument. Flangeway 2nd check rail gauge.

If spirit level is employed for approximate checks then it is required to check the verticality with more accurate technique. This is used to measure the track gauge check-rail gauge check-rail guide face flange groove and superelevation. Provide working instruction on how to check it on a daily basis.

In isolation each strategy can help to reduce unexpected machine failure but taken together they form the hub of a proactive maintenance strategy that will not only identify incipient problems but allows extending machine operating life considerably. An alignment check is to be performed for both inlet and outlet lines. View the industrial use of linear equipment and measuring techniques in a local engineering company.

Machinery alignment is often accomplished in areas that are hazardous unless proper precautions are observed. All other inlets including air inlets must be. Here we describe them individually so that you know when best to use them.

The rotation of the measurement devices around the shaft is similar to that of a clock. 1332 mm to 1365 mm. Laser alignment is an essential component of a viable maintenance strategy for rotating machines.

Desired results expressed in general terms Methods Tools or instruments used to gauge progress toward achieving outcomes Measures Intended performance targets expressed in specific terms. Checking the sensors A simple and quite reliable way to check all the sensors is to run the fan at half speed when the growing rooms are empty. Alignment Profiling and Position Sensing 3 Given a laser and other necessary equipment correctly measure the diameter of a sample of wire using a diffraction method.

To avoid small misalignment in the vertical direction first support from rotary equipment nozzle is used either spring support or adjustable type support. To maintain accuracy measuring and test equipment Is handled and stored using good scientific and engineering Judgment following manufacturers recommendations or a specific procedure if the P1 so directs. If not factor the ground slope into the camber reading.

The measurement will also include correct determination of the effect of positional and angular misorientation of the wire. Lasers in Testing and Measurement. First the Microgage Cylindrical Laser is placed into the chuck and spindle or a collet mount so that the laser beam can project along the axis of rotation.

The four measurement methods are 9-12-3 EasyTurn Multipoint and Continuous sweep. Alignment check must be performed with spring under both in As designed and in locked condition. Methods used to check alignment of curriculum with outcomes curriculum mapping.

For the selection of measurement instruments the set of. As well as maintenance to the RH measuring sensors periodically checking the measuring equipment should also be a standard item on the maintenance chart.

Alignment Tools Steel Shims Stainless Steel Products Machine Alignment

0 Comments